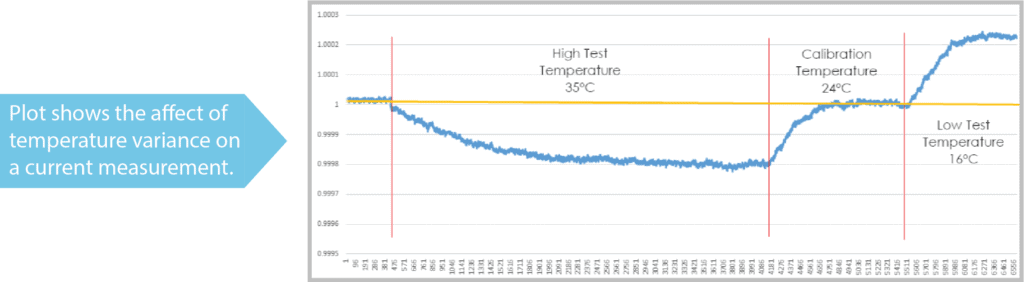

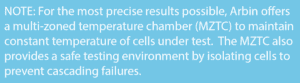

Temperature variance of the test equipment and the device under test will always affect the measurement. This is a physical property that cannot be escaped, but it can be minimized.

Knowing how temperature affects the measurement empowers the researcher when determining the experimental error. When test equipment resolution and precision are sufficient, measurement fluctuation due to temperature will be seen. Gradual temperature changes will gradually skew results data [above], and sudden temperature changes can cause jumps in the data as seen [below]. It is important to use test equipment that is resistant to temperature changes with proper thermal control mechanisms and to control temperature of the test environment.

Translating this into test results…

Arbin defines the affect of temperature on the instrument accuracy as ~0.000185% / 1°C, by using patented shunt designs and high-quality materials that are resistant to temperature fluctuations. Additionally, some of Arbin’s test equipment uses internal thermal control mechanisms that isolate sensitive components and tightly regulate the temperature using techniques developed during a multi-year investigation with partners Ford Motor Company and Sandia National Lab’s metrology department; regarded as one of the best in the world. This technology allows the test equipment to maintain incredibly high precision measurements.

(1) Resolution | (2) Precision | (3) Temperature | (4) Robustness | (5) Accuracy | (6) Software