Introduction End-Of-Line (EOL)

For battery production companies, maintaining the highest quality standards is crucial. Our End of Line (EOL) testing feature is designed to provide comprehensive quality assurance, ensuring that every battery meets your rigorous performance criteria.

Comprehensive Customizable Criteria Checks

Fully Customizable

Define your own battery performance criteria using logical expressions and equations. Tailor the checks to meet the specific needs of your production line.

Precision and Flexibility

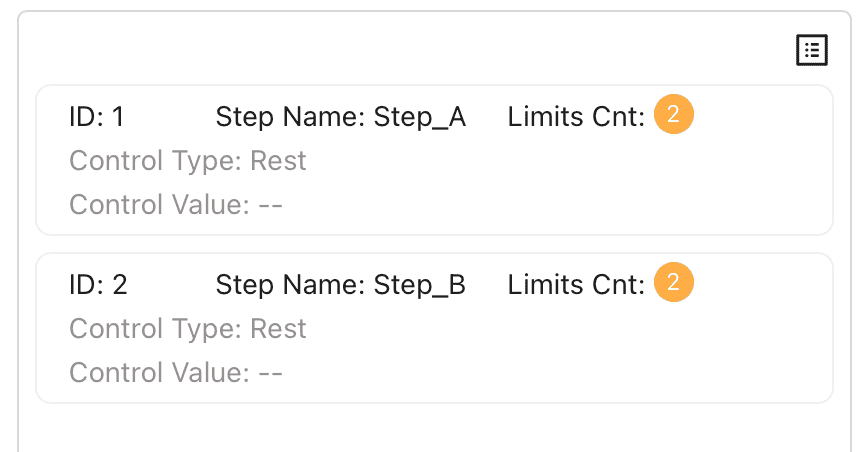

From basic checks to complex multi-step validations, our system ensures that every battery is thoroughly tested to your exact specifications.

Seamless Integration with Schedule Files

Continuous Testing

Combine the EOL feature with our schedule file to create continuous end-of-line testing protocols. This allows for streamlined operations and consistent quality assurance across all production stages.

Automated Testing

Simplify your workflow by automating EOL testing, reducing the need for manual intervention and minimizing errors.

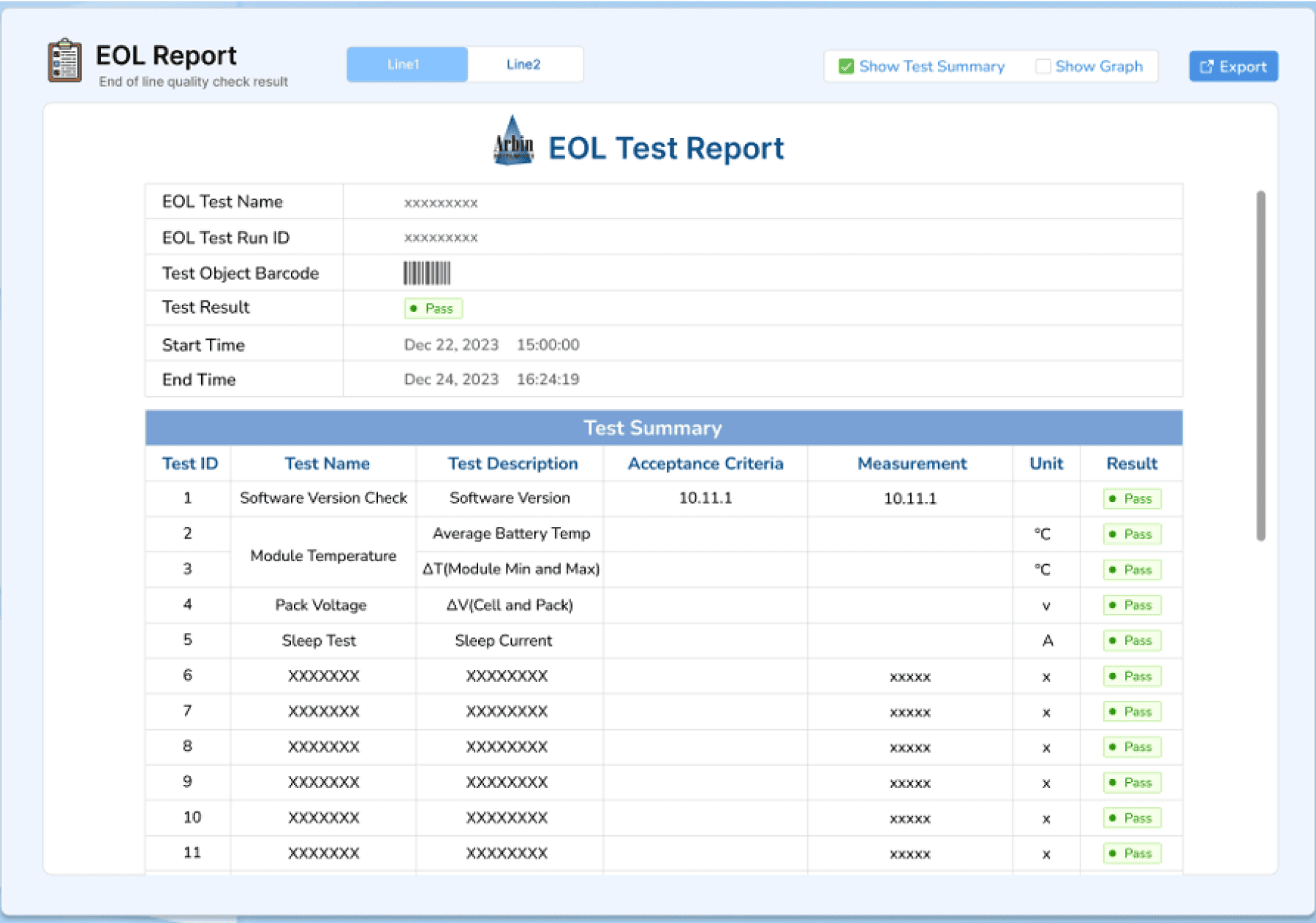

Real-Time Monitoring & Comprehensive Reporting

During-Test Monitoring

Stay informed with our real-time monitoring page, which provides live updates on the testing process. Quickly identify any potential issues as they arise.

Detailed Post-Test Reports

After testing, receive a comprehensive report covering all the criteria checks and any potential failures. These reports provide invaluable insights for improving your production process and ensuring product quality.

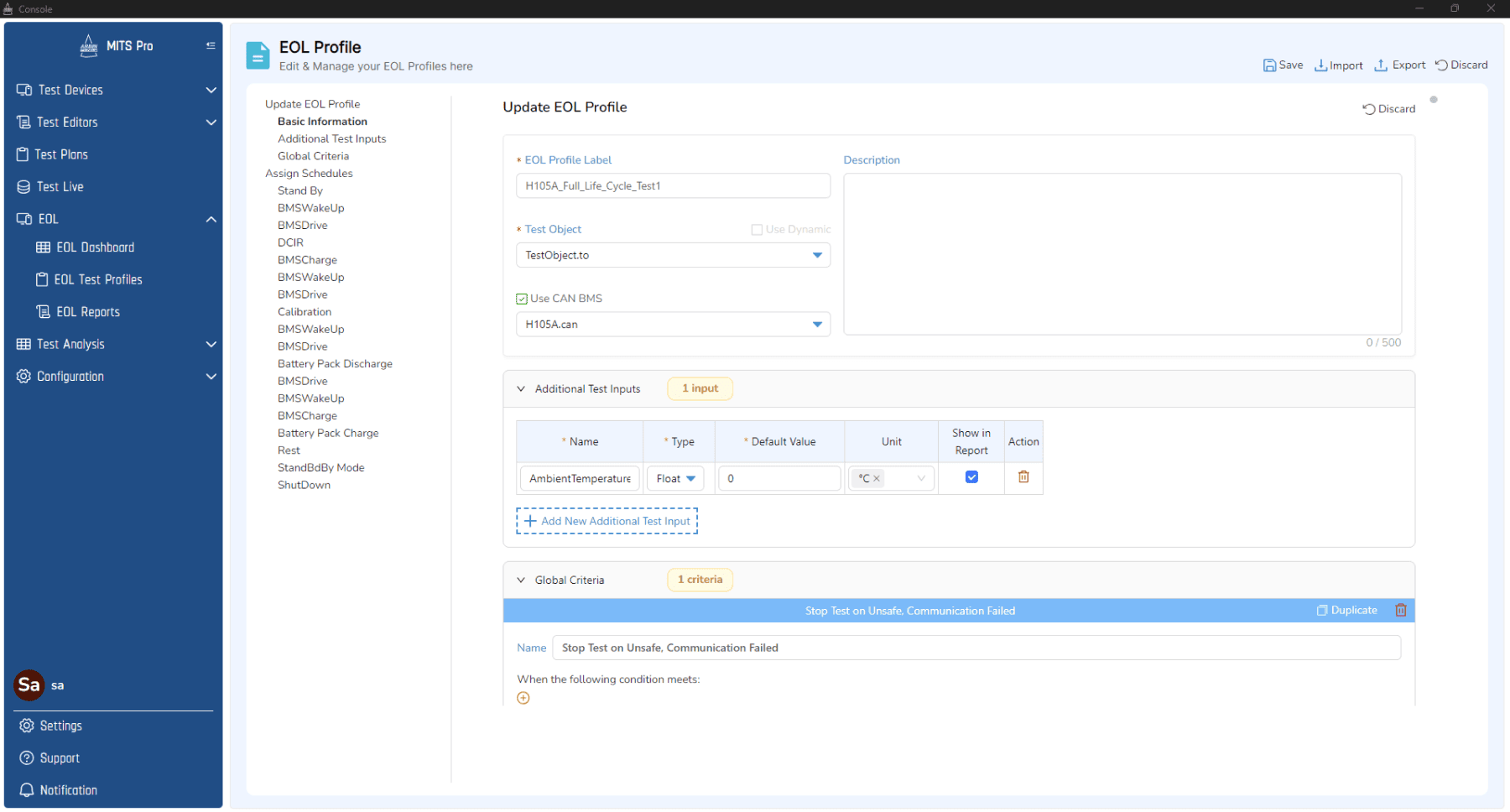

测试进程 Profile

Creating an EOL Profile

Users begin by providing the essential details for the EOL profile, including the label (name), test object, and a description of the test.

Additionally, there is an option to utilize CAN BMS during the testing process.

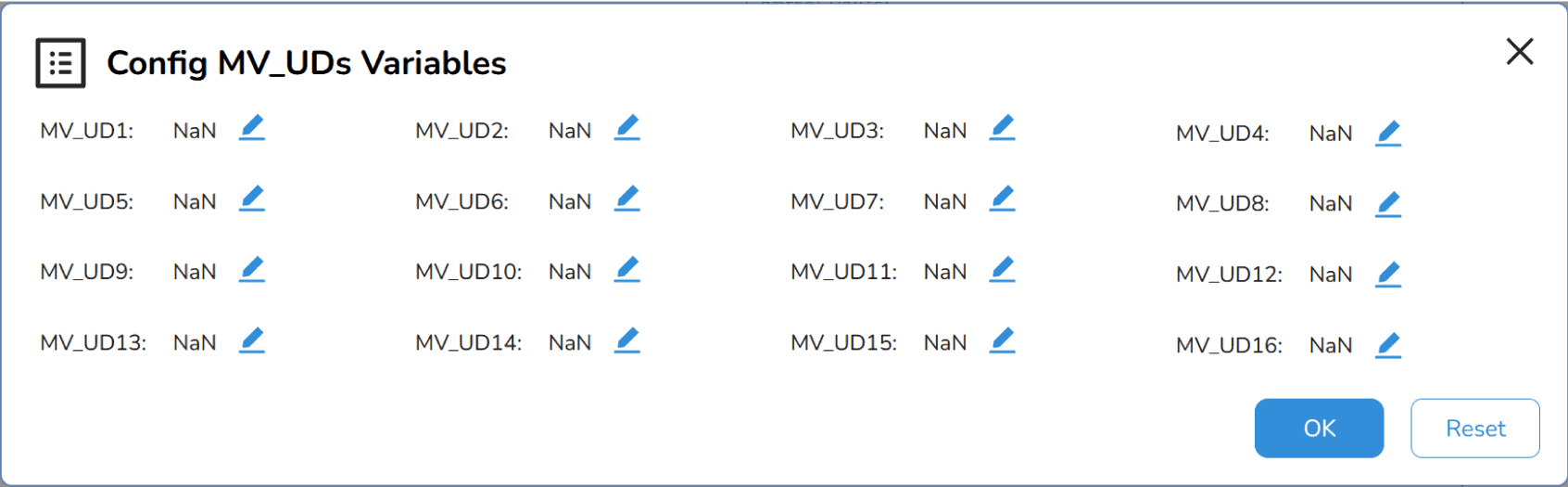

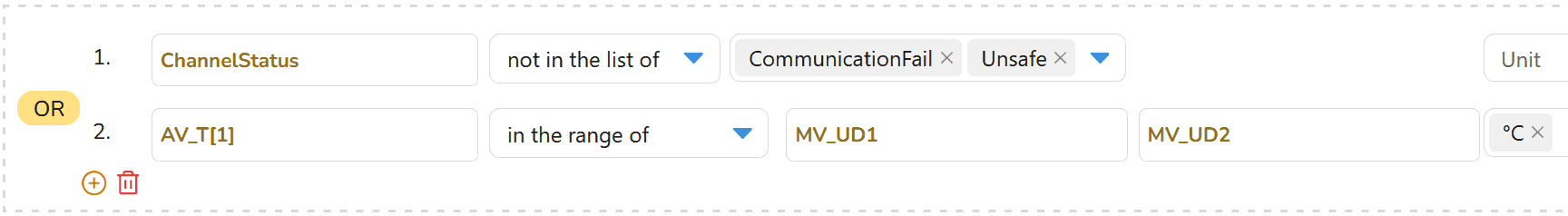

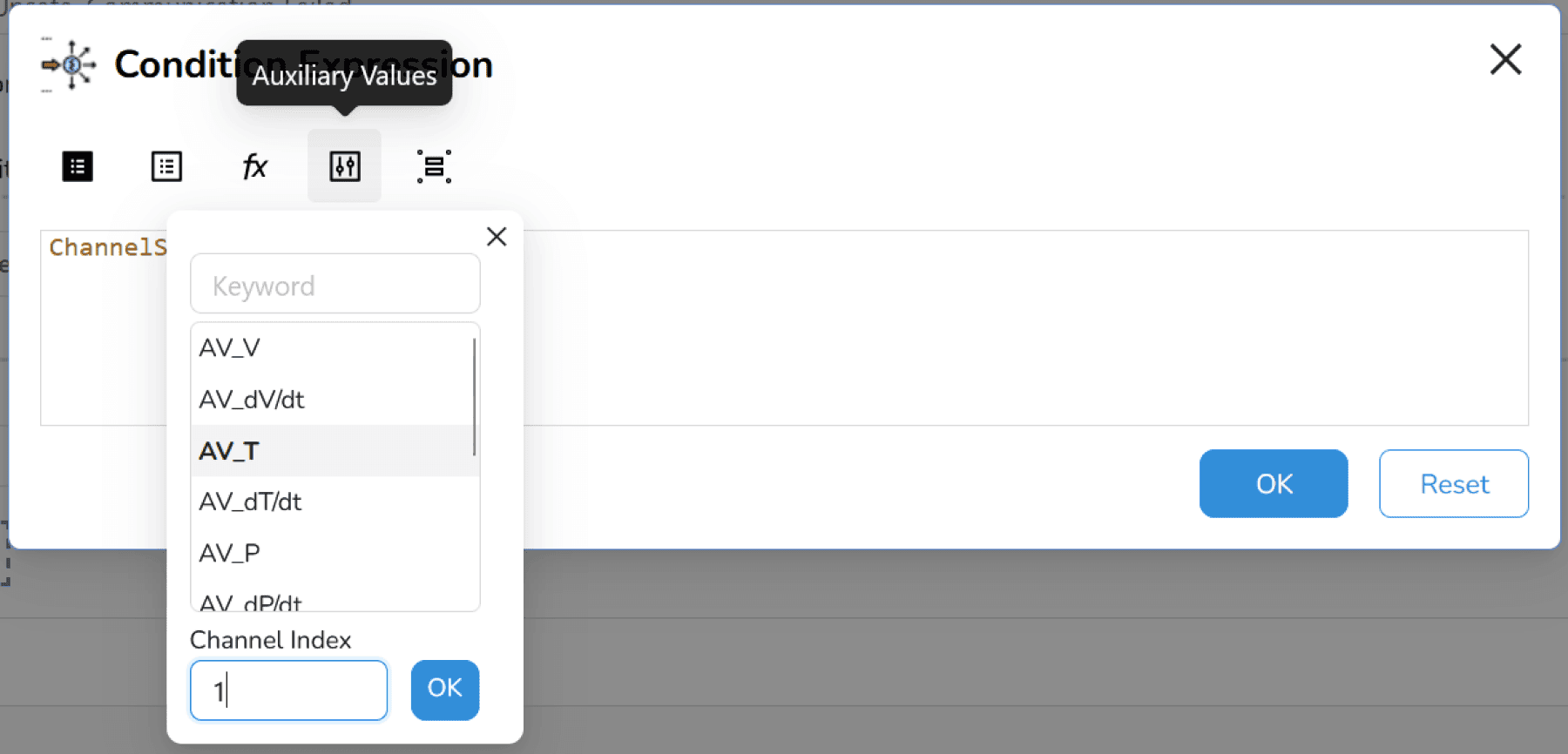

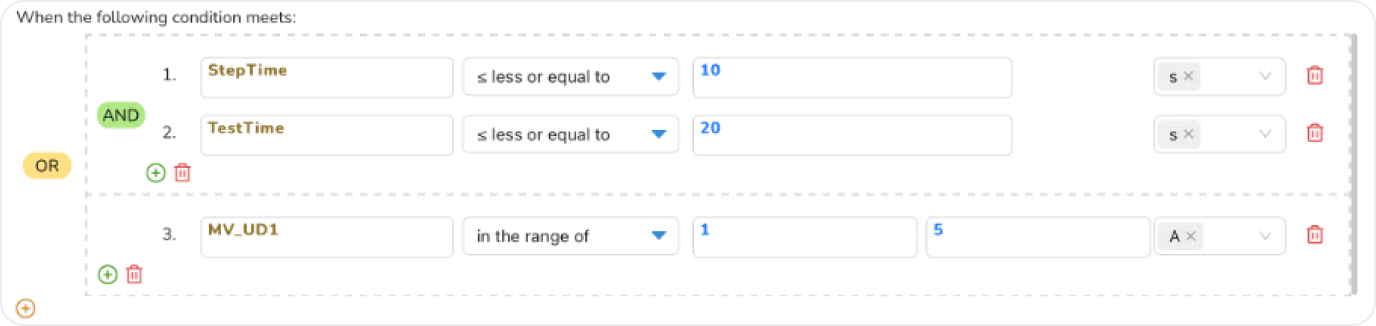

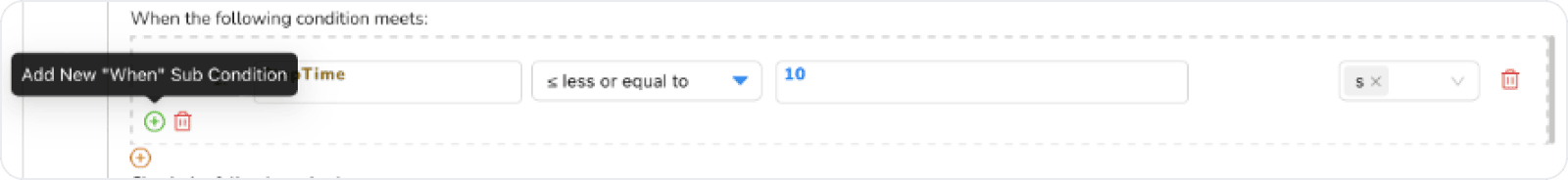

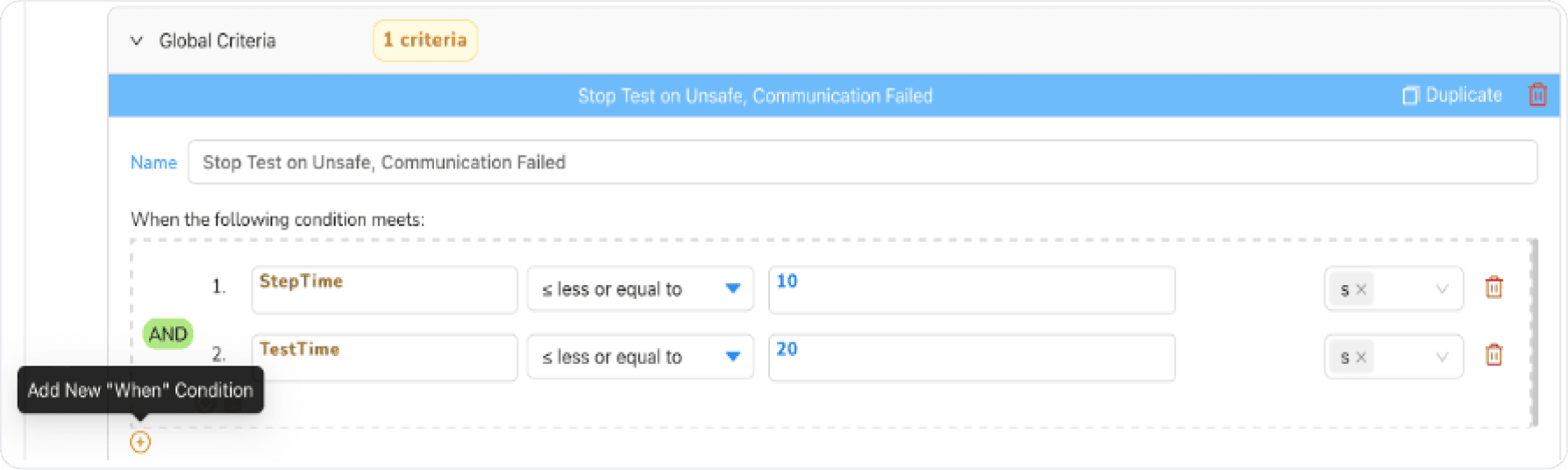

Condition Expression Wizard

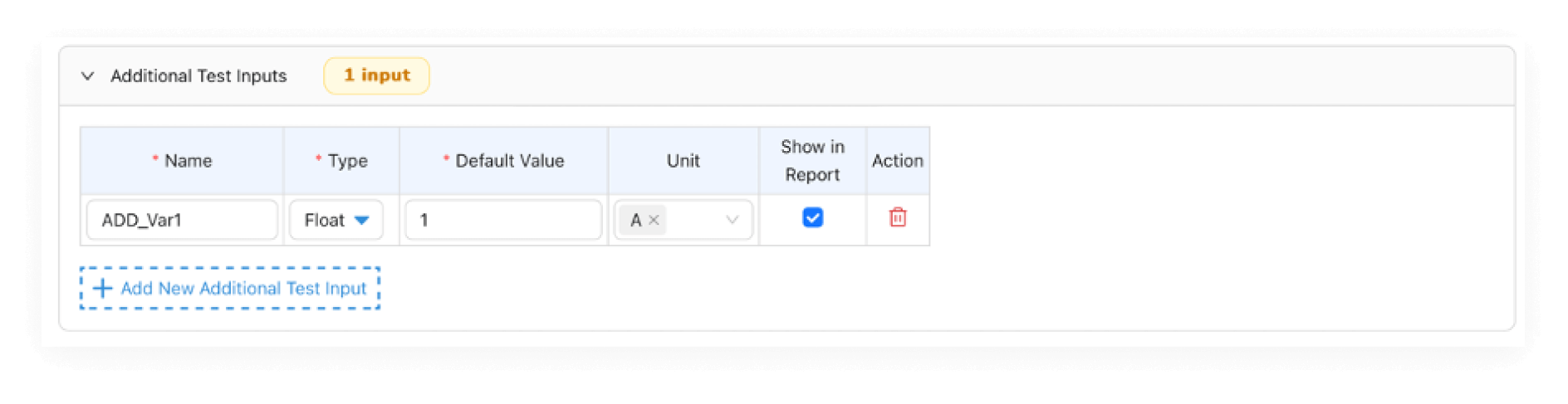

Add New Conditions

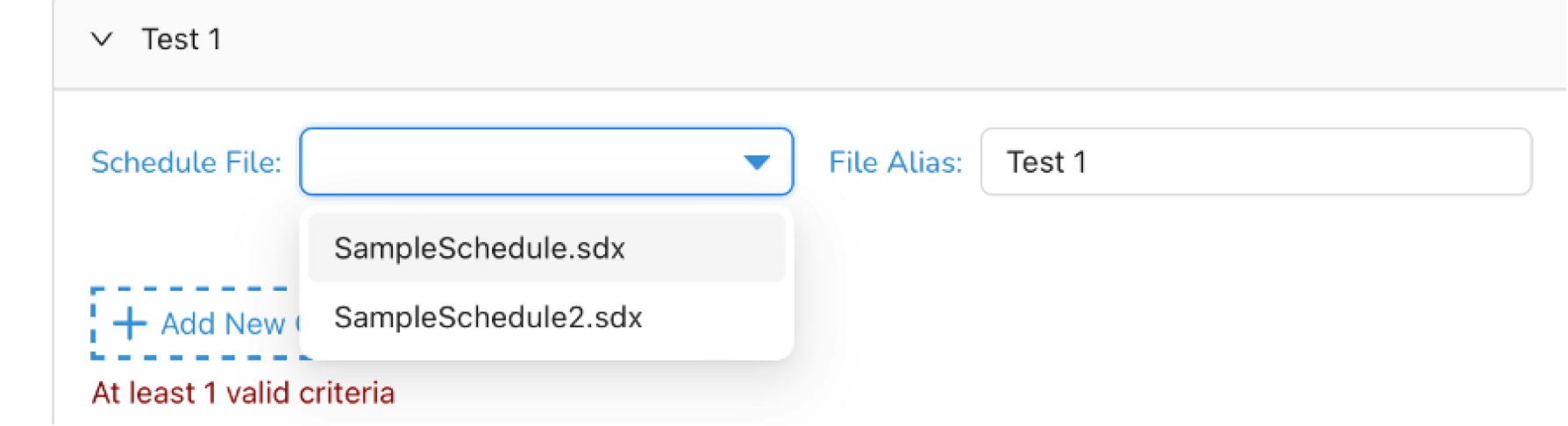

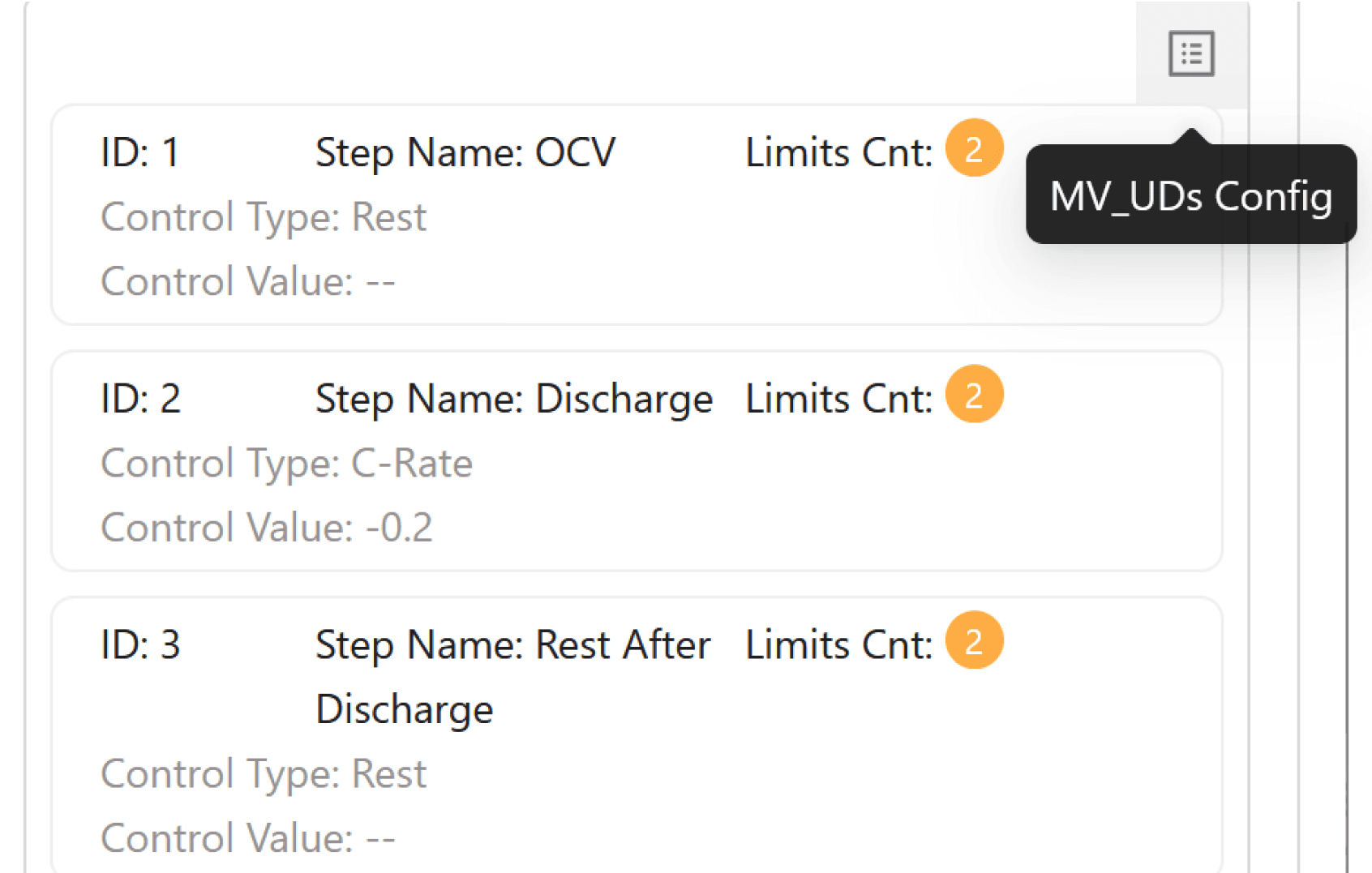

Select the Schedule and Create Criteria

for the Schedule

Users can choose a schedule file from the dropdown menu and assign it a file alias for easy reference.

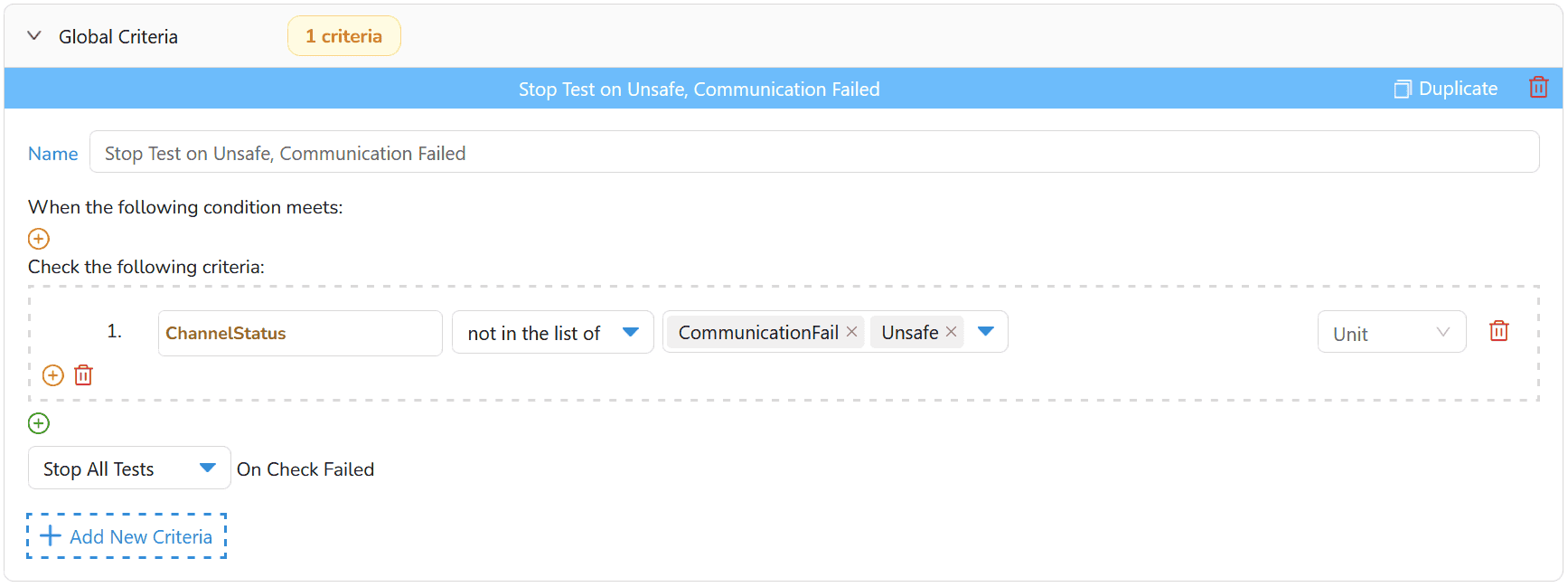

Test Criteria Engine

测试进程 Report