Smart Data Logging (Acquistion) User's Guideline

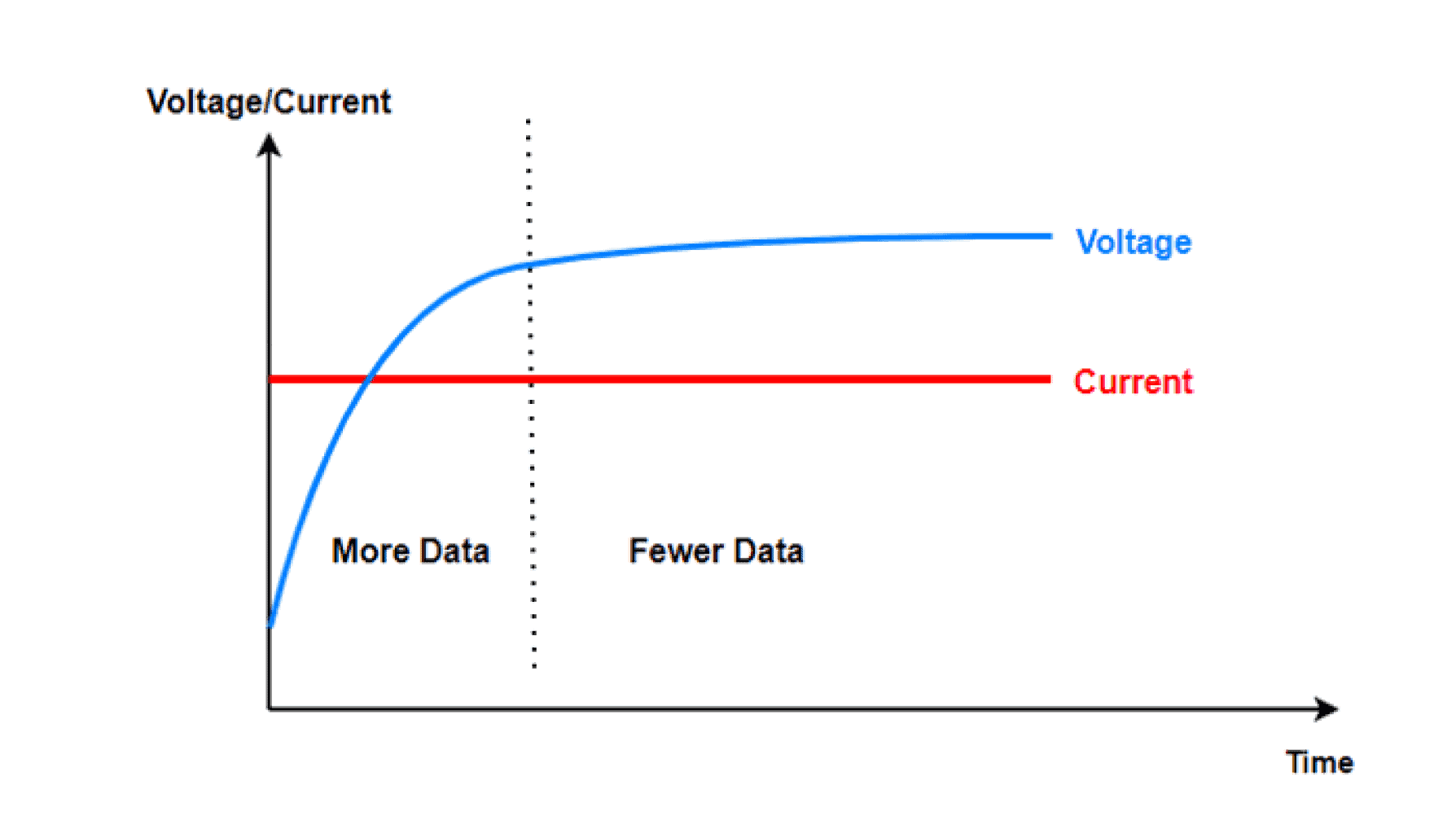

For battery researchers and testers who need to study battery performance, data logging is an important factor, it can provide more accurate current, voltage, time, and temperature data to increase the efficiency of testing analysis.

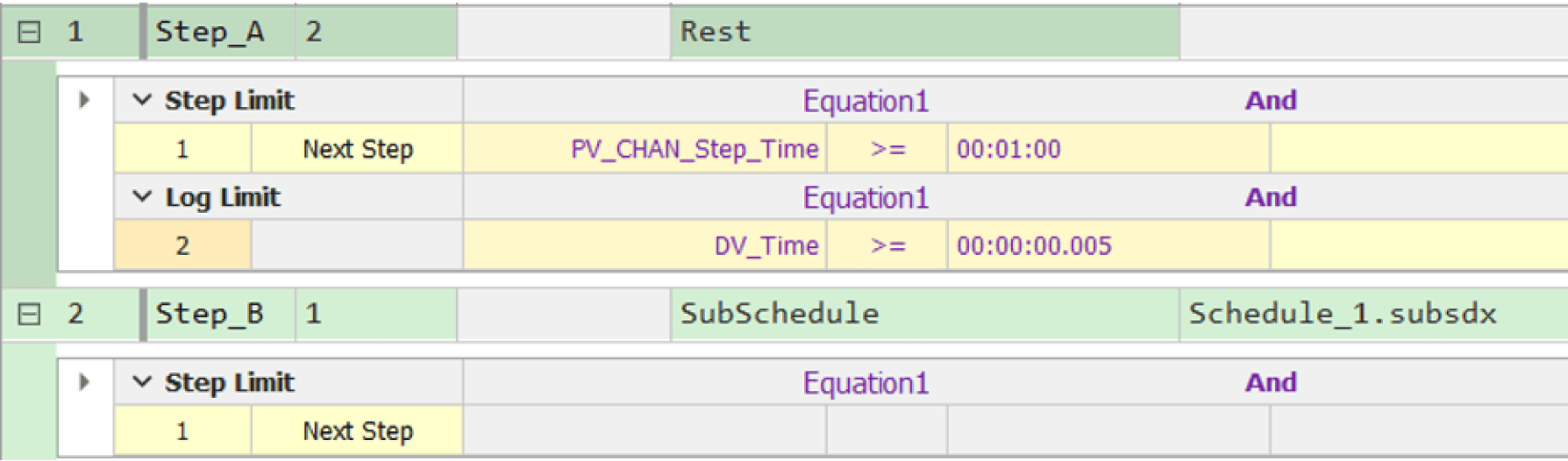

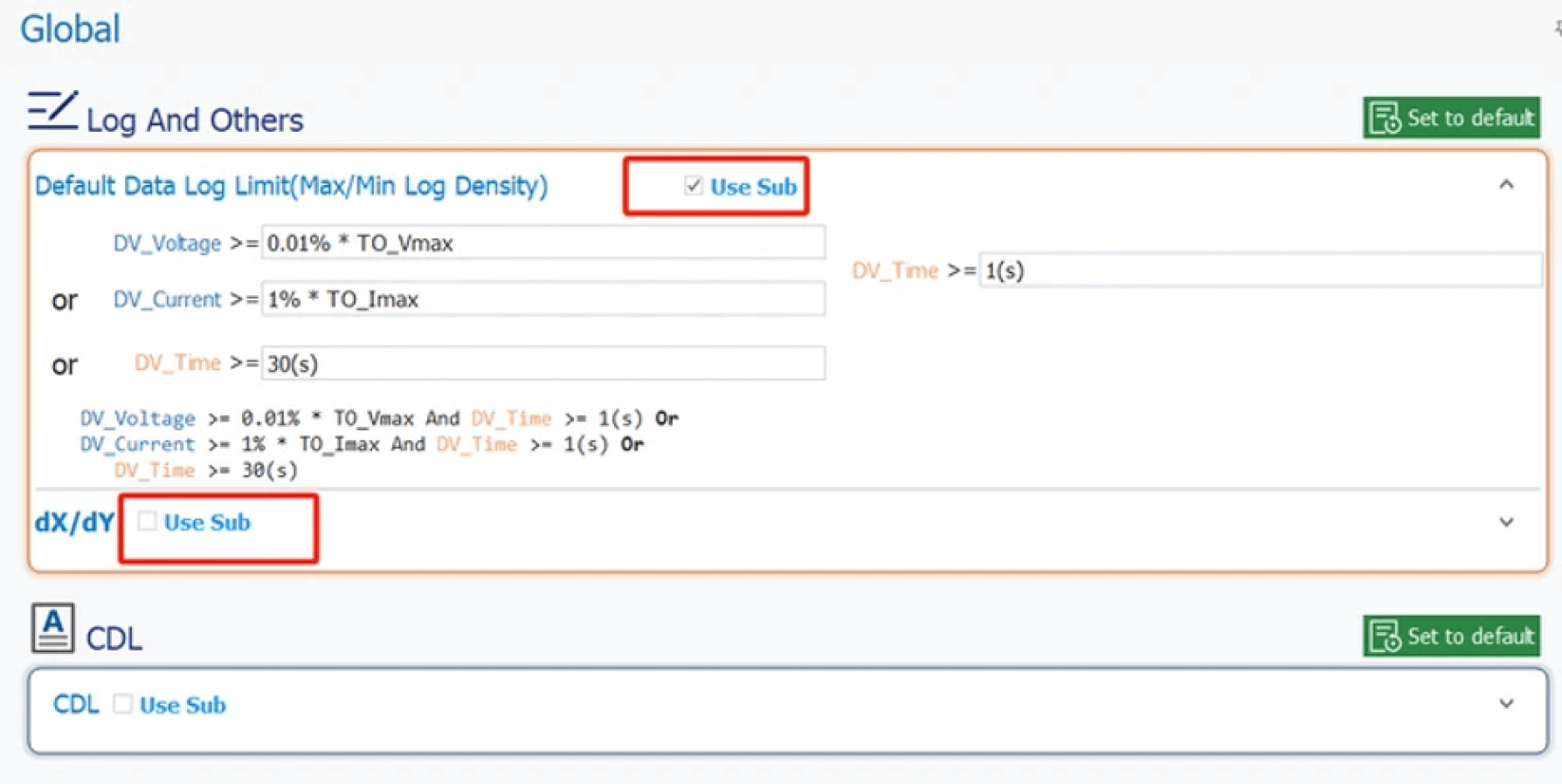

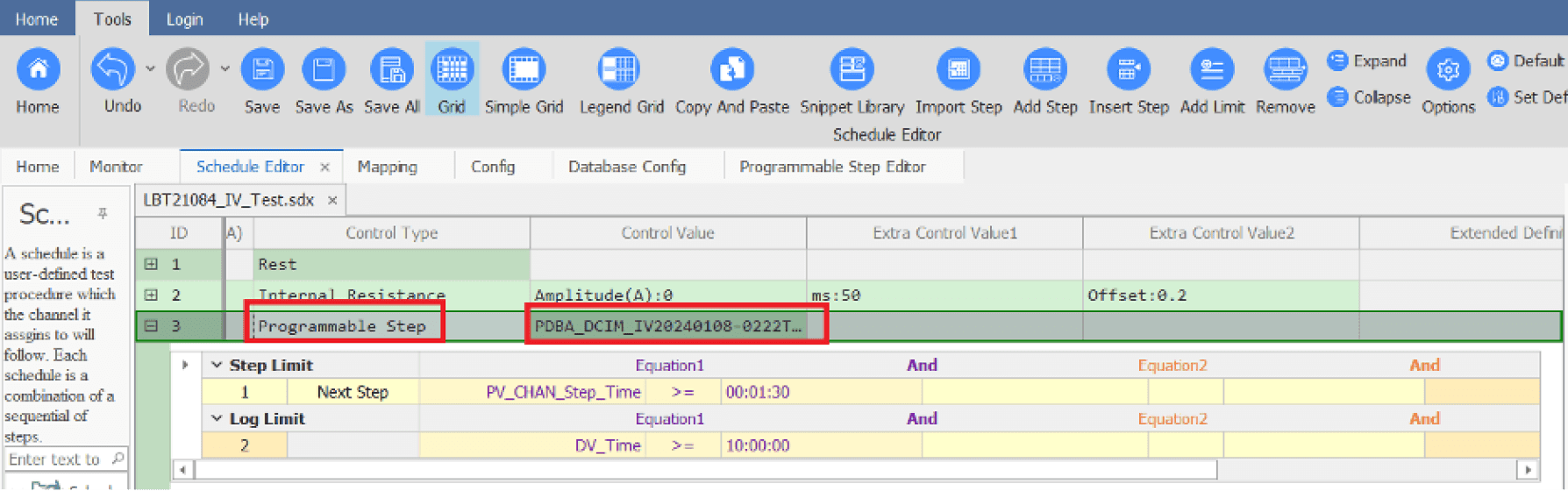

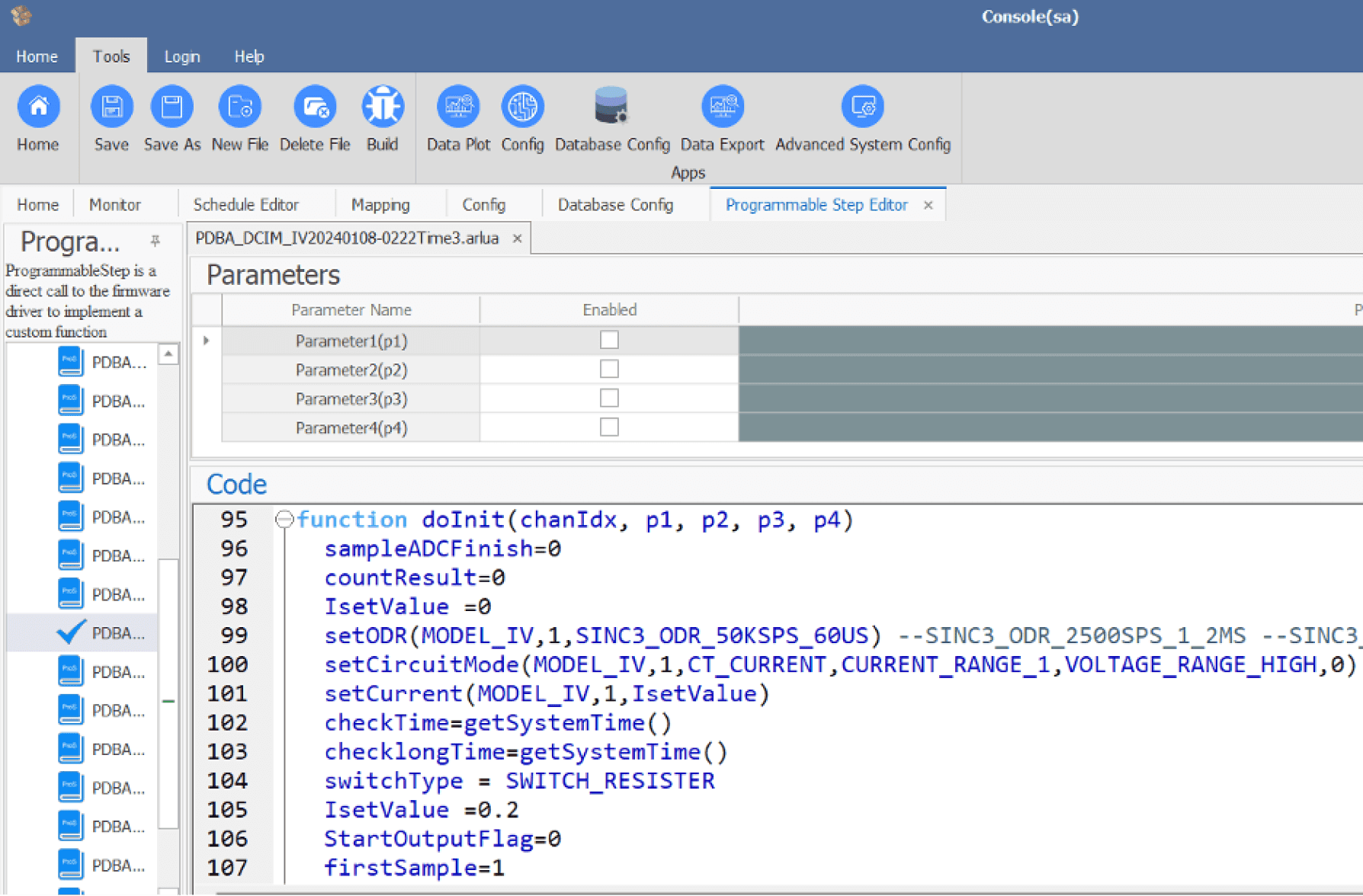

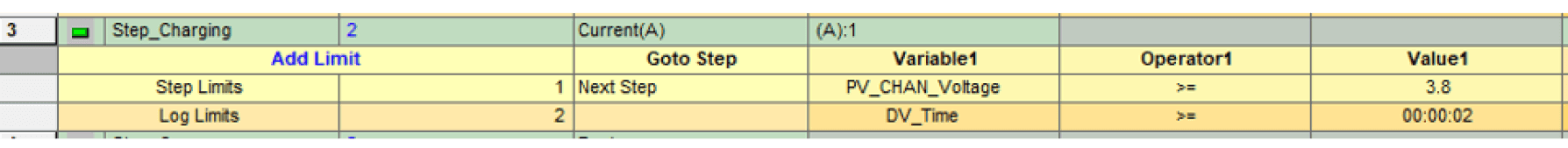

These technical strategies will need to apply Smart Data Logging (SDL) feature in the battery testing industry, the Arbin Testing System can be used with SDL filtering unchanged data measurement in the experiment, reducing data logging rates, increasing efficiency, and preventing overload of data collections that cause the System Under Test (SUT) to fail the experiment.

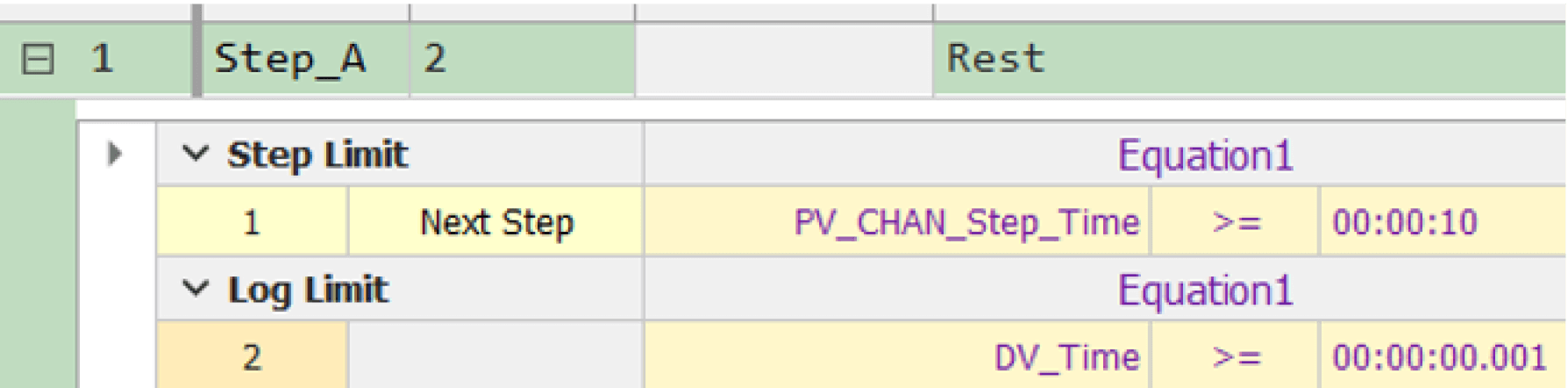

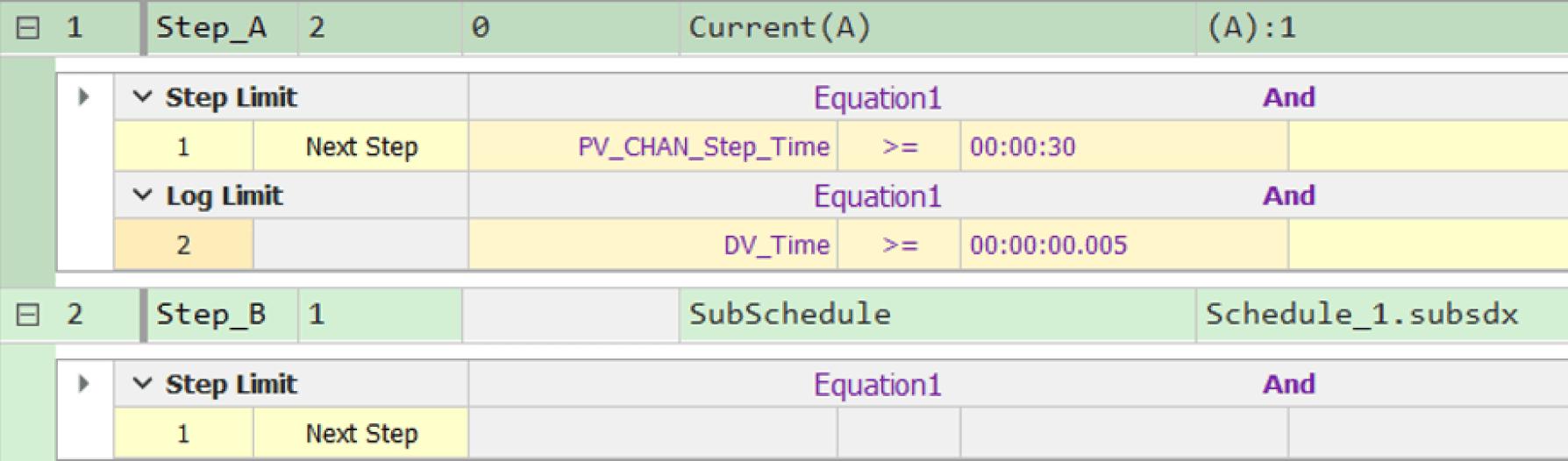

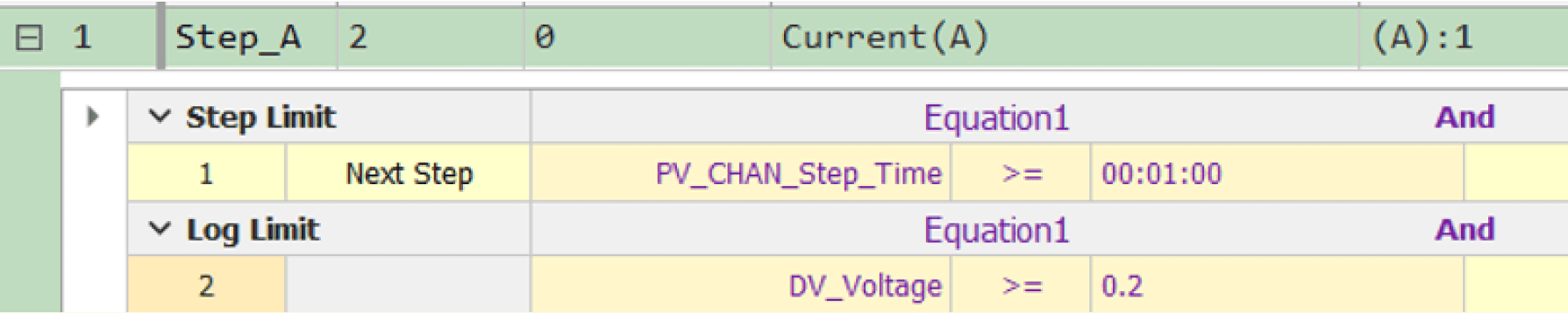

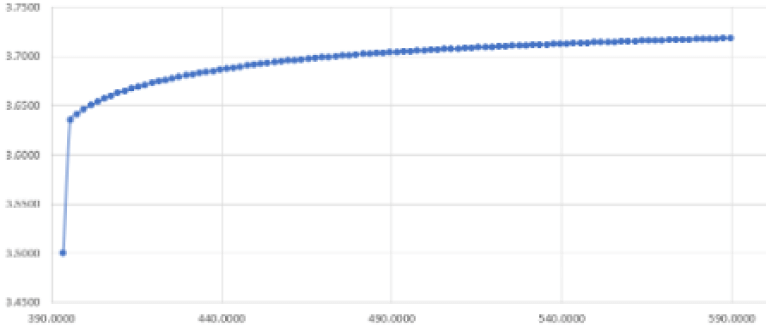

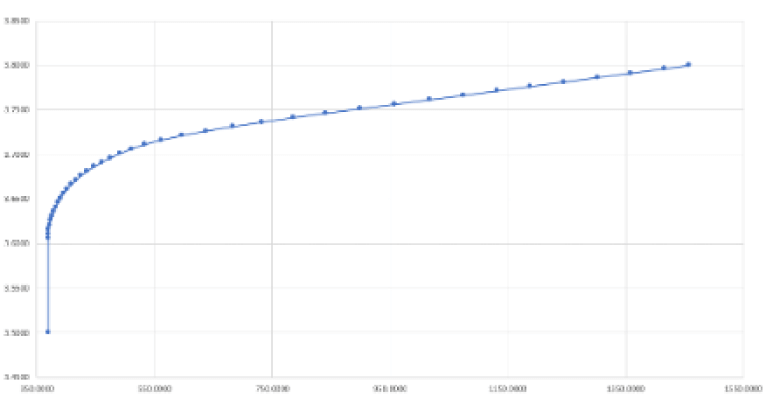

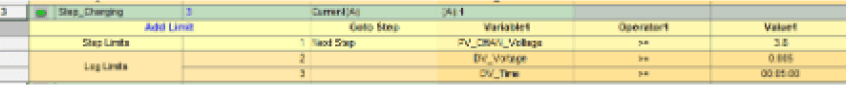

Criteria on change logging data point

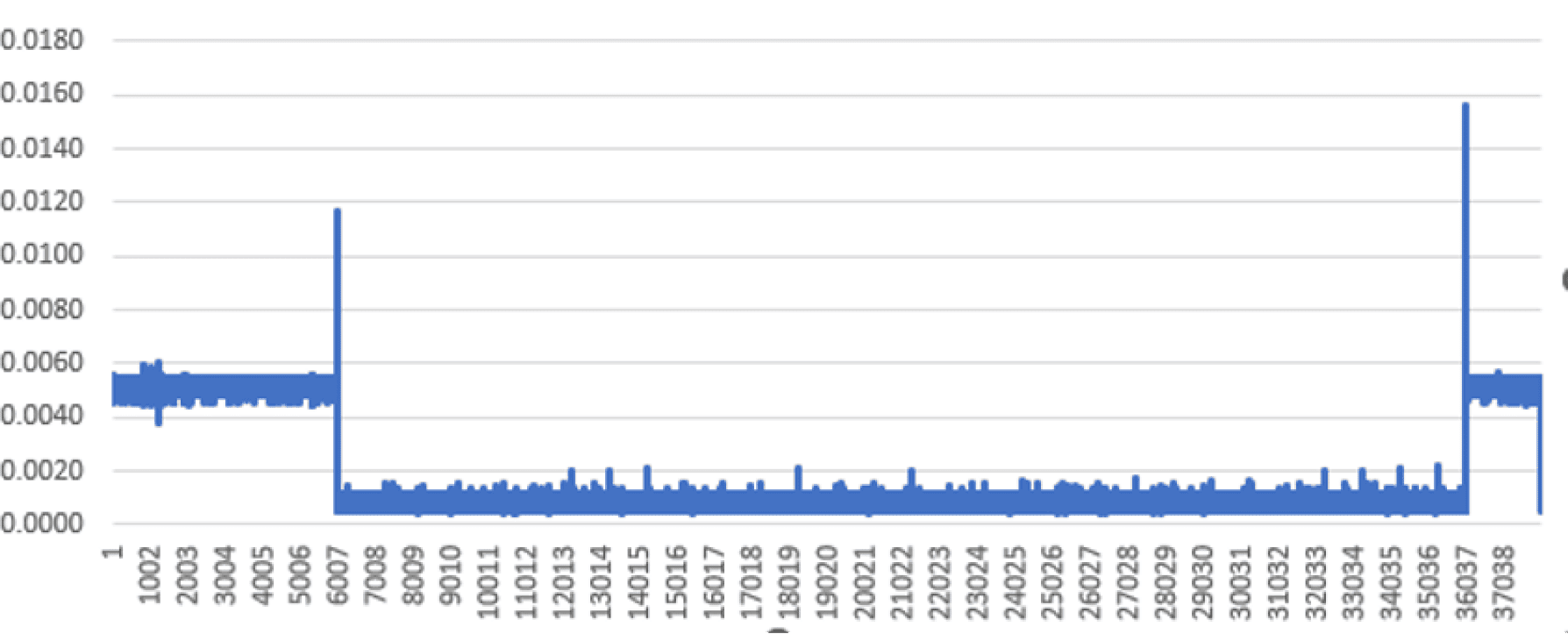

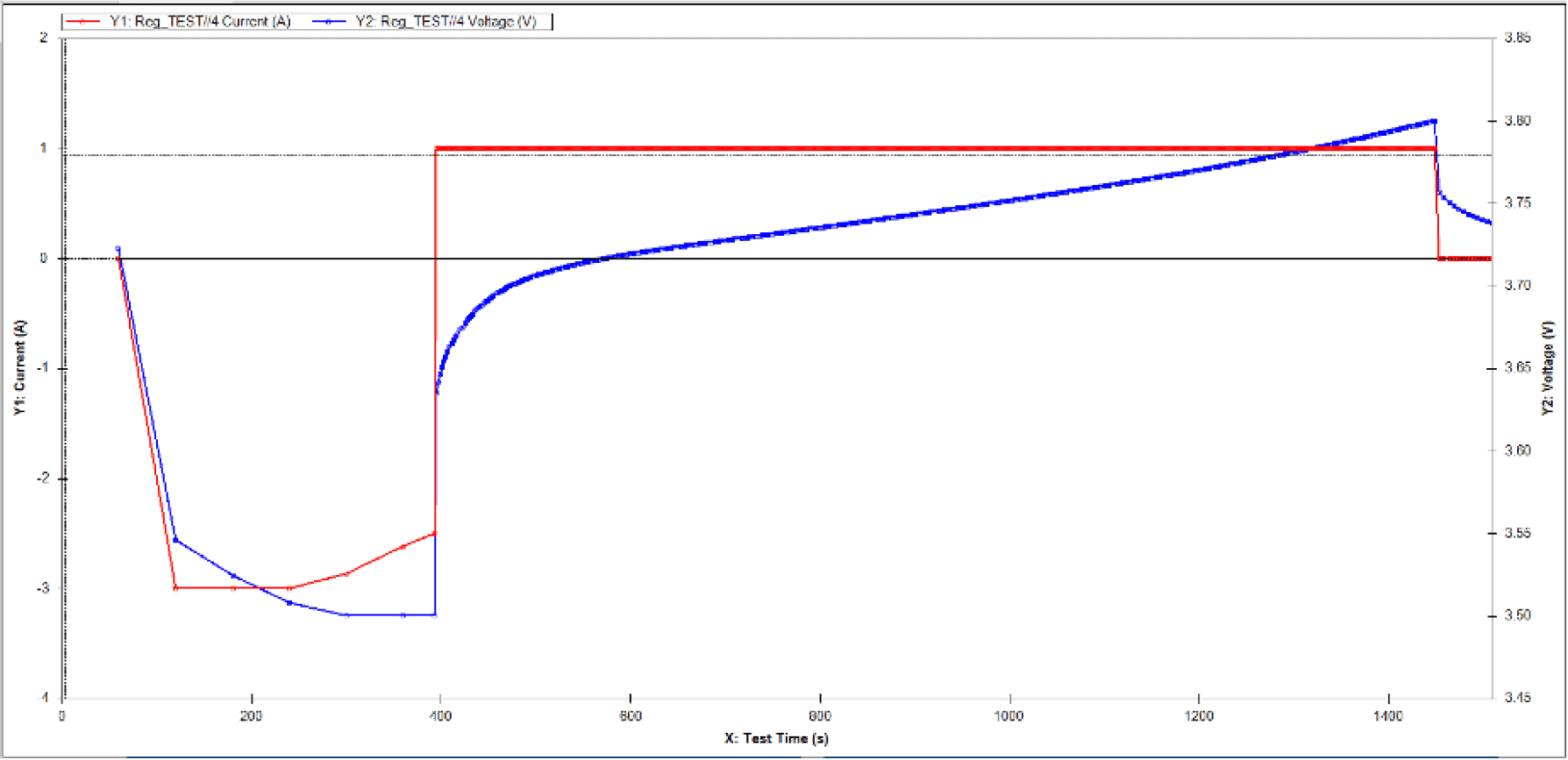

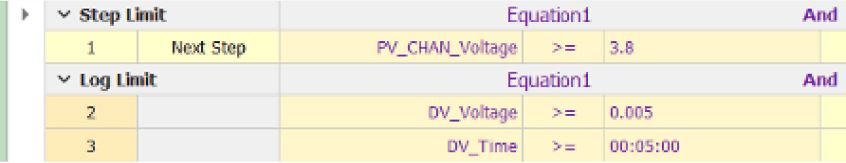

Figure 1. Regular logging (left) vs SDL (right)

SDL-Disable

SDL-Enable

Arbin Smart Data Logging Solutions

总结

Using SDL with Arbin cycler can provide a more accurate and efficient way of data logging when doing the multi-channel testing on cells.

This integration stands as a testament to the commitment to excellence in scientific research and technological advancements, offering a cutting-edge solution for those seeking a robust and efficient approach to data acquisition.